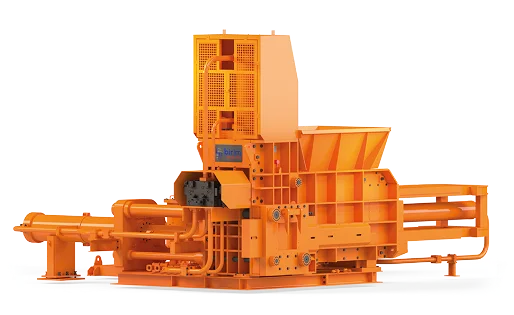

Tiger - Lid Baler

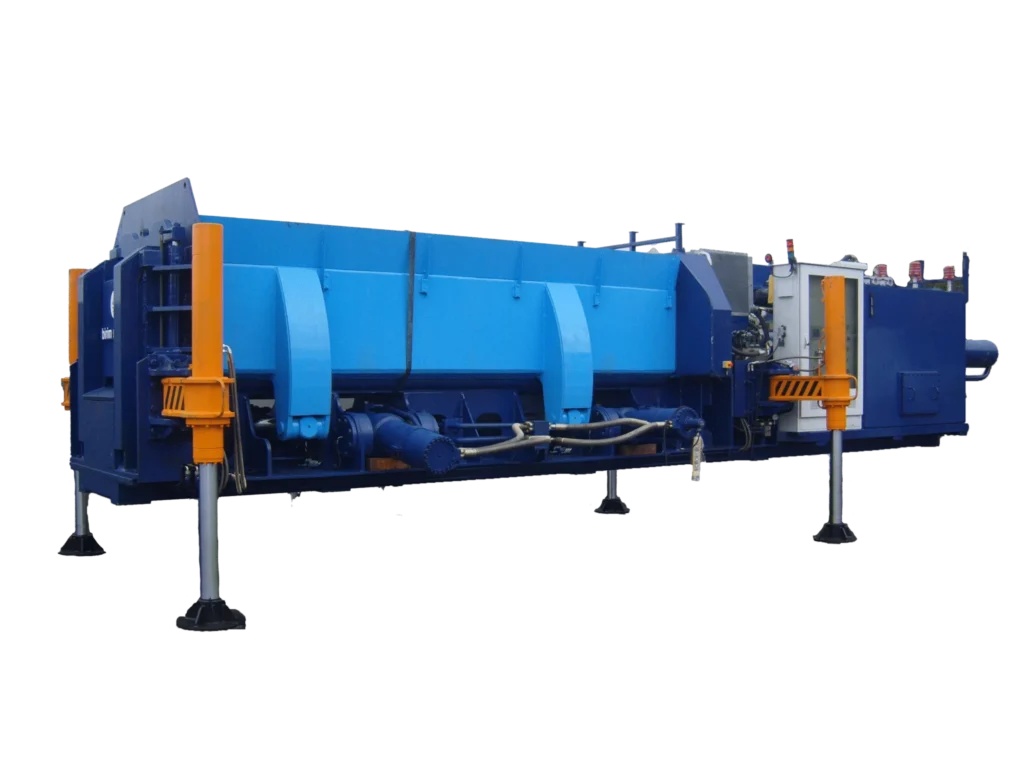

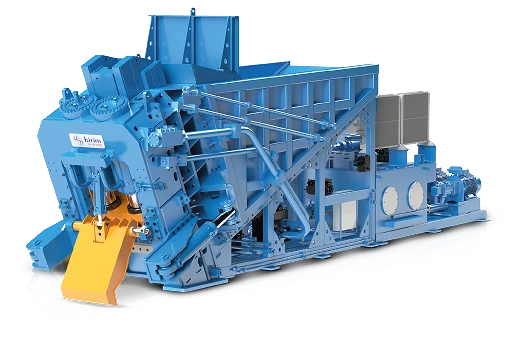

Baling Press with 3 compression

About Tiger

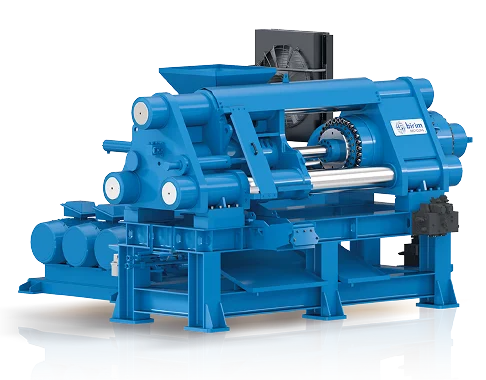

Our Tiger model Balers (Baling Presses) offer a flexible operation in terms of input materials and capacity requirements. Whether it is a Steel Mill or a Scrap Yard , our balers are ready to press. With their premium components and well built structure they last long for sustainability. That’s why they roar out “Ready, anytime and anywhere”

Operation

- Capacity : 1 – 40 tons per hour.

- Suitable input materials : Steel, Aluminum, Stainless Steel, Copper and Brass in forms of Sheets, Car parts, Profiles, Mixed Scrap, Chips, Cables, Cans and Wires.

- Automatic and manual operation

- Reduced scrap feeding time by the hopper.

- High density bales with a variety of bale sizes from 25×25 to 60×60 cm.

- Remote diagnosis and trouble shooting via modem connection enables quick technical assistance

Structure

- Strong built body parts for Heavy Duty operation.

- Wear plates made of premium Hardox products with different profile shapes to suit the input material.

- Non-contact sensors in the machine prevents interruptions due to dirt and falling scrap.

- Heavy duty cylinders designed and manufactured in house.

- Hydraulic system designed and manufactured in house.

- Tier 1 parts in the machine supplied by Bosch Rexroth, Siemens, Baluff, Hydac.

Get in Touch

Contact us for information!

FAQ

General Questions About Tiger

Find answers to common questions about Tiger here. If you need more information, feel free to contact us!

What is the processing capacity of the machine?

The capacity varies by model and ranges from 2 to 30 tons per hour, making it suitable for various scales of operation.

What types of materials can this machine handle?

It is capable of processing ferrous and non-ferrous materials such as Fe, Al, Cu, Cr-Ni, as well as sheets, aluminum extrusions, and turnings.

What features enhance the machine’s efficiency and reliability?

The machine offers automatic remote-controlled operation, fast scrap feeding via hopper, contactless sensors on all cylinders, improved oil filtration, and remote troubleshooting—all designed to ensure smooth, efficient, and low-maintenance performance.