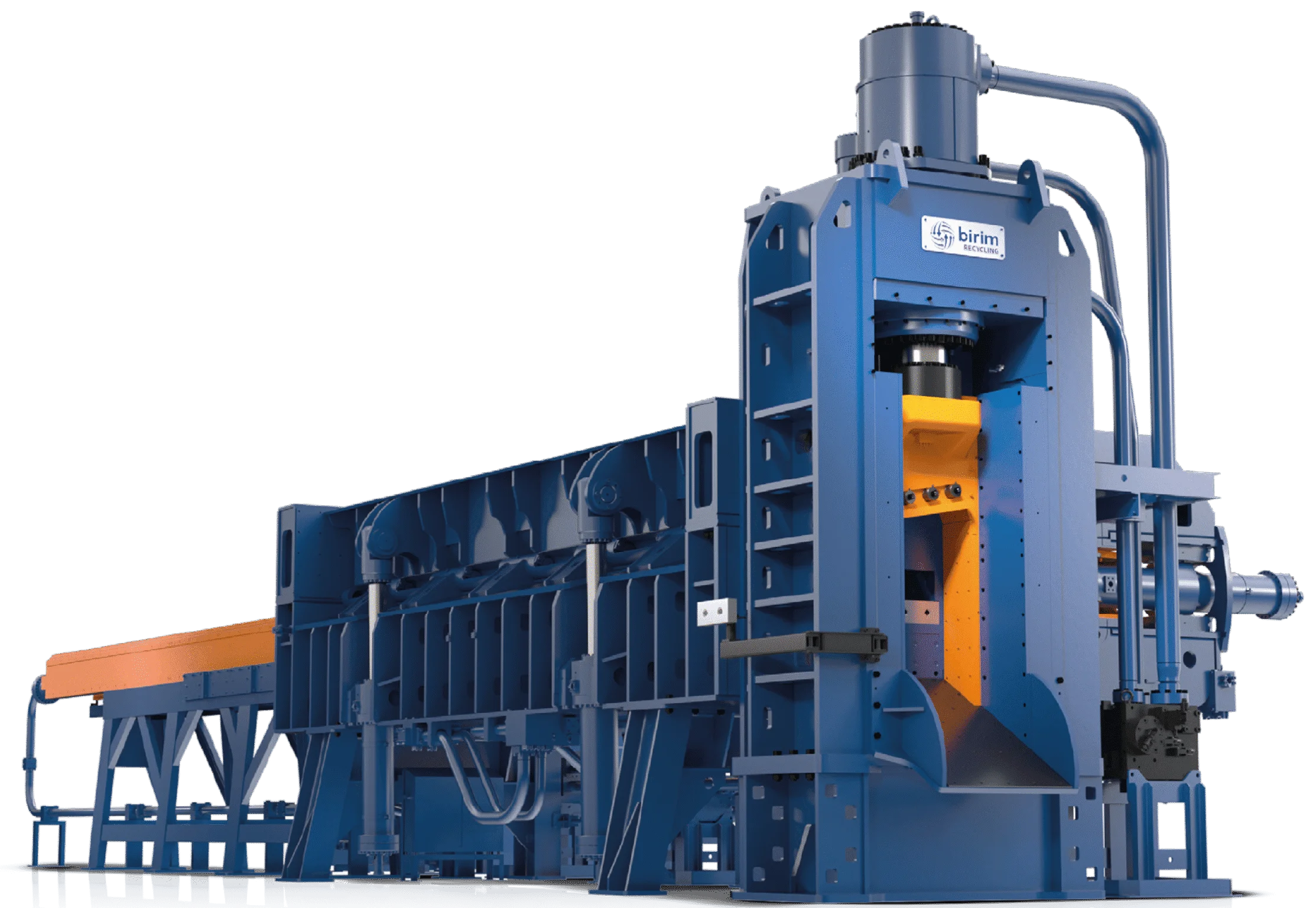

Shark

Wing Compression Shears

About Shark Wing Shear

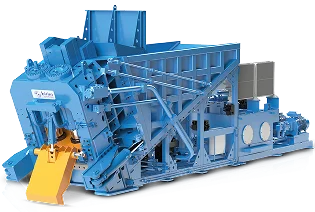

This high-efficiency scrap processing machine, available in stationary, mobile, and semi-mobile versions, compresses both heavy and light scrap to increase density before automatically shearing or baling at high capacities (8–30 ton/h for shearing, 10–35 ton/h for baling). Designed for iron-steel mills and scrap yards, it handles HMS 1&2, pipes, sheets, ELVs, and mixed scrap. Featuring short stroke programming, remote diagnostics, no-contact sensors, and automatic lubrication, the system ensures continuous, energy-efficient operation with top-quality hydraulic and electronic components from brands like Linde, Rexroth, Siemens, and ABB.

Operation

- Capacity : 10 to 35 tons / hour

- Suitable input materials : HMS 1, HMS 2, Sheet, ELV, Mixed Scrap

- Automatic and manual operation

- Compresses heavy and light scrap and increases the density before shearing.

- Cutting length can be chosen as per demand.

- Advanced oil filtering system for trouble free operation

- Automatic lubrication

- Stationary – Mobile and Semi Mobile versions available.

- Diesel and Electric Power options.

- Remote diagnosis and trouble shooting via modem connection enables quick technical assistance

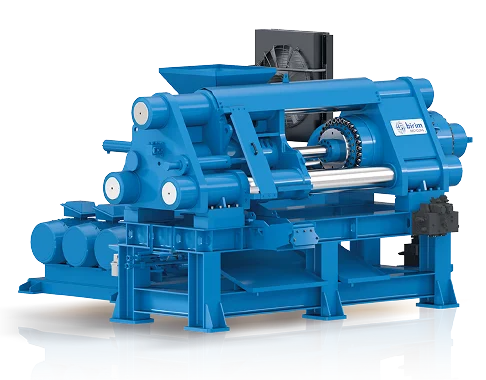

Structure

- Strong built body parts for Heavy Duty operation.

- Wear plates made of premium Hardox products.

- Non-contact sensors in the machine prevents interruptions due to dirt and falling scrap.

- Heavy duty cylinders designed and manufactured in house.

- Hydraulic system designed and manufactured in house.

- Tier 1 parts in the machine supplied by Bosch Rexroth, Siemens, Baluff, Hydac.

Get in Touch

Contact us for information!

FAQ

General Questions About Shark

Find answers to common questions about Shark here. If you need more information, feel free to contact us!

What is the processing capacity of the machine?

The machine offers a shearing capacity between 8 to 30 tons per hour and a baling capacity between 10 to 35 tons per hour, depending on the model and scrap type.

Which power options are available for this machine?

The machine is available with both diesel and electric power options, allowing flexibility based on the operational environment.

What features ensure efficient and low-maintenance operation?

Features like the short stroke program, no-contact sensors, automatic lubrication, oil filtering system, and remote diagnostics via modem contribute to efficient, continuous, and low-maintenance performance.