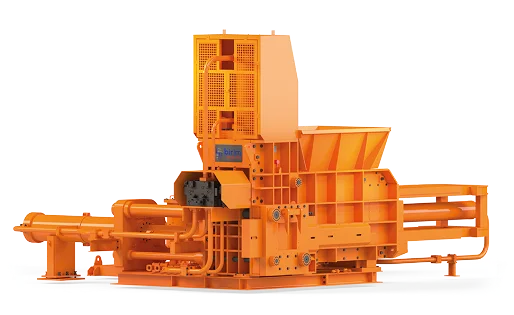

Can Baler

UBC Baler | Aluminum Baler | Baler Press

About Can Baler

This fully automatic scrap processing machine, with a capacity of 0.8 to 1.6 tons per hour, is specifically designed for handling UBC (Used Beverage Cans), ensuring efficient, continuous operation with minimal maintenance.

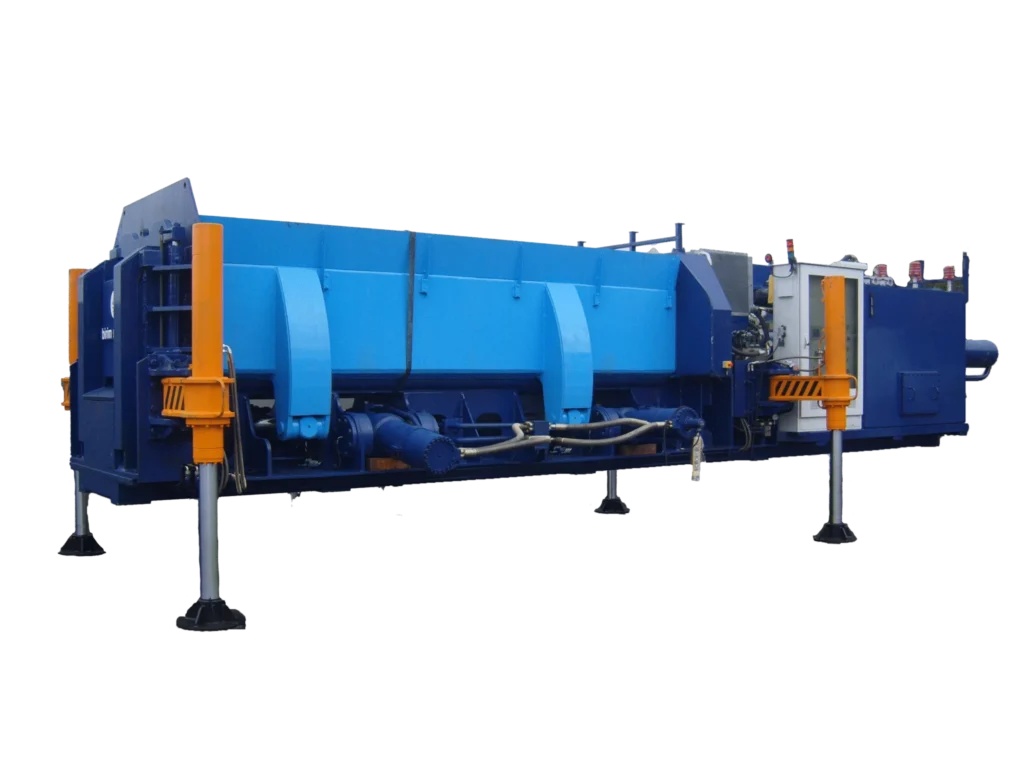

Operation

- Capacity : 0,8 – 1,6 tons per hour.

- Suitable input materials : UBC (Used Beverage Can)

- Automatic operation

- Automatic feeding by the magnetic seperator conveyor.

- High density bales with a 30 x 50 bale.

- Remote diagnosis and trouble shooting via modem connection enables quick technical assistance

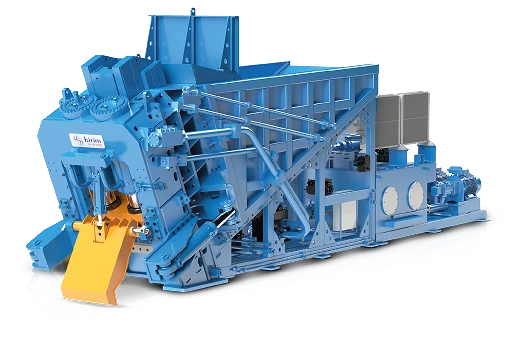

Structure

- Strong built body parts for Heavy Duty operation.

- Wear plates made of premium Hardox products.

- Non-contact sensors in the machine prevents interruptions due to dirt and falling scrap.

- Heavy duty cylinders designed and manufactured in house.

- Hydraulic system designed and manufactured in house.

- Tier 1 parts in the machine supplied by Bosch Rexroth, Siemens, Baluff, Hydac.

Get in Touch

Contact us for information!

FAQ

General Questions About Can Baler

Find answers to common questions about Can Baler here. If you need more information, feel free to contact us!

What is the processing capacity of the machine?

The machine has a processing capacity ranging from 0.8 to 1.6 tons per hour, making it ideal for compact, continuous processing of UBC (Used Beverage Cans).

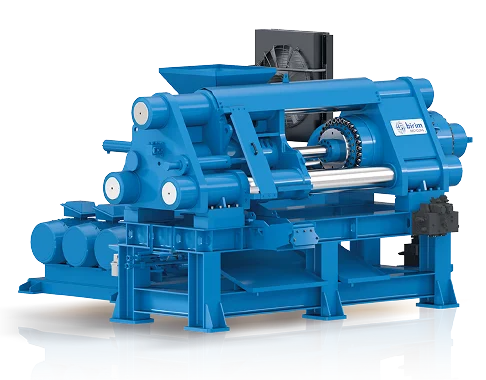

Which features ensure reliable and low-maintenance operation?

The machine includes no-contact sensors to avoid recalibration, an oil filtering system for uninterrupted operation, and remote diagnostics via modem for quick technical assistance.

Maecenas et odio dignissim

It features a robust body with original Hardox anti-wear plates, high-quality chrome-coated and honed hydraulic cylinders, and uses premium components from leading brands like Linde, Rexroth, Siemens, and Phoenix Contact.