Briquette Press

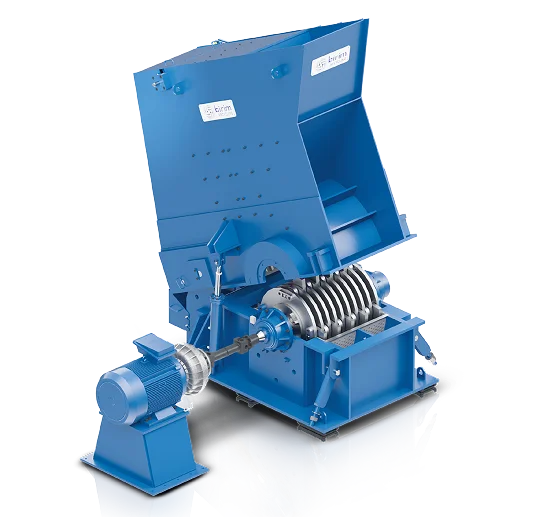

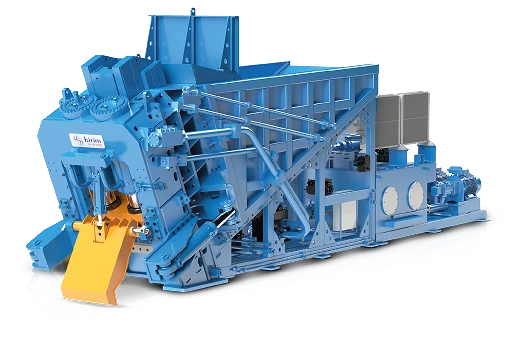

Chip Processing

About Briquette Press

Birim Recycling Briquetting Presses offer a flexible operation in terms of input materials and capacity requirements. It can either be supplied as a single machine or an integrated plant with screens, shredders and conveyors. With their premium components and well built structure; they last long for sustainability.

Operation

- Capacity : 0.5-10 tons per hour.

- Suitable input materials : Steel, Cast Iron, Aluminum, Stainless Steel, Copper and Brass in forms of Chips, Swarf and Sludge.

- Full automatic operation

- Low energy consumption thanks to high tech hydraulic system.

- Single machine or Integrated plant operarion with screen, shredder and conveyors.

- High density of briquettes up to 5.5 t/m3 (Steel), 2.4 t/m3 (Aluminum), 7.8 t/m3 (Copper)

- Remote diagnosis and trouble shooting via modem connection enables quick technical assistance

Structure

- Strong built body parts for Heavy Duty operation.

- Easy and quick to change tools and wear parts for better maintenance.

- Heavy duty cylinders designed and manufactured in house.

- Hydraulic system designed and manufactured in house.

- Tier 1 parts in the machine supplied by Bosch Rexroth, Siemens, Baluff.

Get in Touch

Contact us for information!

FAQ

General Questions About Briquette Press

Find answers to common questions about [post_title] here. If you need more information, feel free to contact us!

What is the capacity range of this briquetting machine?

The machine offers a capacity range between 0.5 to 10 tons per hour, depending on the model, making it suitable for various operational scales.

What are the key features that ensure efficient and automated operation?

The machine features fully automatic operation with a cycle time of 12 seconds, remote connection for quick troubleshooting, a touchscreen display for easy control, and adjustable features to accommodate different materials.

What materials and components are used to ensure durability and reliability?

The machine is built with a strong body and wear-resistant materials, high-quality heavy-duty cylinders with hardened and chrome-coated piston rods, and hydraulic and electronic parts from top-tier brands such as Linde, Rexroth, Siemens, and Phoenix Contact.