Chip Processing

Scrap Chip Processing turns machining waste into a controlled, melt-ready feedstock. Loose chips, swarf, and sludge trap coolant, oxidize quickly, and cost money to store and move. A Birim Recycling solution built around a Briquetting press and a Briquetting machine reduces volume, improves handling, and produces dense briquettes that melt more efficiently.

This category lists three machines used in Scrap Chip Processing:

- Briquetting Press (core compaction): the Briquetting press is the primary Briquetting machine in most Scrap Chip Processing lines.

- Screen (conditioning): a Screen stabilizes Scrap Chip Processing by delivering consistent material to the Briquetting press and the Briquetting machine.

- Shredder (size reduction): a Shredder supports Scrap Chip Processing by reducing long turnings and bulky scrap before the Briquetting press.

How Scrap Chip Processing works

A typical Scrap Chip Processing workflow has one goal: feed the Briquetting press with consistent, manageable material so the Briquetting machine can compact at stable pressure. Depending on your scrap stream, you may:

- Use a Screen to separate oversize pieces and stabilize the feed to the Briquetting press and Briquetting machine.

- Use a Shredder to cut long turnings so Scrap Chip Processing remains continuous and the Briquetting machine does not bridge or stall.

- Run the Briquetting press as a stand-alone Briquetting machine or as part of an integrated Scrap Chip Processing plant with conveyors.

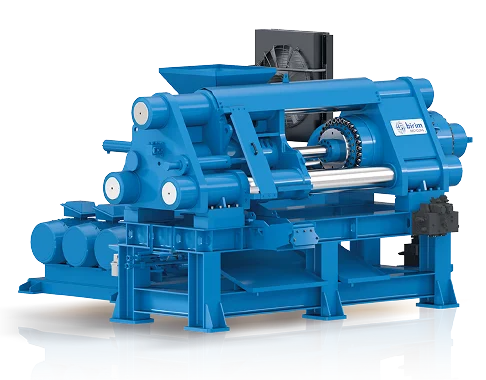

Briquetting Press: flexible compaction across metals

The Briquetting press is designed for flexible input materials and broad capacity requirements, which is why it is central to Scrap Chip Processing. You can buy the Briquetting press as a single Briquetting machine, or as an integrated plant with Screen, Shredder, and conveyors for end-to-end Scrap Chip Processing.

Operation

A Briquetting press should match your material, moisture, and throughput. Key operating points for the Briquetting press and Briquetting machine:

- Capacity: 0.5–10 tons/hour (model dependent), covering both small and high-throughput Scrap Chip Processing.

- Input materials: Steel, Cast Iron, Aluminum, Stainless Steel, Copper, and Brass as chips, swarf, and sludge—ideal for a Briquetting press and Briquetting machine.

- Full automatic operation: the Briquetting machine runs repeatable cycles for predictable Scrap Chip Processing.

- Low energy consumption: high-tech hydraulics help the Briquetting press and Briquetting machine stay efficient.

- Standalone or integrated: one Briquetting press today, expandable Scrap Chip Processing tomorrow with Screen, Shredder, and conveyors.

- High briquette density: up to 5.5 t/m³ (Steel), 2.4 t/m³ (Aluminum), 7.8 t/m³ (Copper), helping the Briquetting machine deliver tight, uniform briquettes.

- Remote diagnosis: modem-based support for the Briquetting press and Briquetting machine reduces downtime in Scrap Chip Processing.

Structure

In high-duty Scrap Chip Processing, durability and serviceability matter. The Briquetting press has a strong body for heavy-duty work, and the Briquetting machine is designed for quick tool and wear-part changes. Heavy-duty cylinders are designed and manufactured in-house. The hydraulic system is designed and manufactured in-house. Tier-1 components from Bosch Rexroth, Siemens, and Balluff support long service life for the Briquetting press and stable automation for the Briquetting machine.

Screen: stable separation and steady feeding

A Screen strengthens Scrap Chip Processing by improving input consistency before compaction. Mixed chip streams often include fines, varying sizes, and occasional oversize pieces. By separating and routing material, the Screen protects the Briquetting press from jams and helps the Briquetting machine maintain a steady cycle.

Use a Screen in Scrap Chip Processing to:

- Remove oversize pieces that could stress the Briquetting press or interfere with the Briquetting machine.

- Deliver a more uniform fraction so the Briquetting press forms consistent briquettes and the Briquetting machine holds stable pressure.

- Reduce operator interventions by keeping Scrap Chip Processing predictable upstream of the Briquetting press.

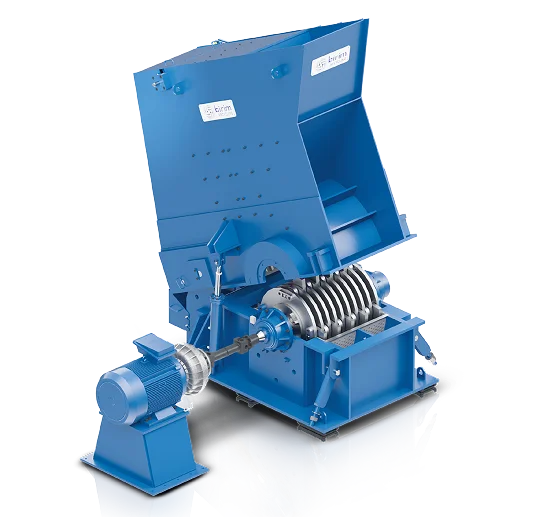

Shredder: size reduction for turnings and mixed scrap

When Scrap Chip Processing includes long turnings or bulky scrap, the Shredder becomes essential. Upstream size reduction prevents bridging, improves flow, and helps the Briquetting press receive manageable input. That stability allows the Briquetting machine to run continuously and keeps Scrap Chip Processing aligned with your throughput targets.

Operation

The Birim Makina Scrap Shredder is built for continuous Scrap Chip Processing:

- Motor power options: 55 kW / 110 kW / 200 kW

- Rotor speed: 1000 rpm

- Suitable inputs: metal turnings, machining chips, incineration scrap, castings (motor and gearboxes), light aluminum profiles, pressed rolls, small white goods, tin cans

- Output capacity: turnings up to 18 t/h; castings up to 7 t/h; aluminum profiles up to 4 t/h; small white goods up to 3.5 t/h

- Full automatic, continuous shredding: electric drive supports uninterrupted Scrap Chip Processing feeding to the Briquetting press and the Briquetting machine

- Recycling result: reduced scrap size improves melting efficiency, especially when Scrap Chip Processing finishes with a Briquetting press

Structure

The Shredder features a heavy-duty welded body, a reversible rotor to extend hammer life, and replaceable original Hardox wear plates. A tiltable upper body gives fast maintenance access, supporting Scrap Chip Processing uptime. Rotor diameters range from 890–1125 mm, rotor lengths from 730–1420 mm, and the machine weight ranges from 8–34 tons depending on model.

Typical layouts | Metal Chip Processing Layouts

Below are common ways to combine a Screen and Shredder with a Briquetting press and a Briquetting machine:

- CNC chips → Screen → Briquetting press: compact Scrap Chip Processing where the Briquetting machine focuses on densification and coolant recovery.

- Long turnings → Shredder → Screen → Briquetting press: balanced Scrap Chip Processing that protects the Briquetting machine and improves briquette consistency.

- Mixed scrap → Shredder → conveyors → Screen → Briquetting press: complete Scrap Chip Processing where the Briquetting press runs with stable input and minimal stoppages.

How to specify the right setup

To specify Scrap Chip Processing quickly, define: material type, moisture level, hourly volume, and scrap shape. If you handle wet chips or sludge, size the Briquetting press and Briquetting machine for throughput and moisture variability. If you process long turnings, add a Shredder so Scrap Chip Processing stays continuous and the Briquetting machine receives flowable material. If your stream is inconsistent, add a Screen to protect the Briquetting press and stabilize the Briquetting machine cycle.

Next step

Send your material list and target tons per hour. Birim Recycling can propose a Scrap Chip Processing layout centered on the right Briquetting press, the right Briquetting machine, and the right conditioning with Screen and Shredder.

Buyer checklist / RFQ inputs

Use this quick checklist to define your project scope before you request pricing:

- Confirm Scrap Chip Processing target (reduce volume, recover coolant) for your Briquetting press and Briquetting machine.

- State Scrap Chip Processing material mix so the Briquetting press and Briquetting machine can be sized correctly.

- Share Scrap Chip Processing hourly volume to select Briquetting press capacity and Briquetting machine cycle profile.

- Indicate Scrap Chip Processing moisture level to set Briquetting press pressure and Briquetting machine tooling.

- Describe Scrap Chip Processing chip shape so the Briquetting press and Briquetting machine feed can be stabilized.

- If Scrap Chip Processing includes long turnings, add Shredder before the Briquetting press and Briquetting machine.

- If Scrap Chip Processing includes mixed sizes, add Screen to protect the Briquetting press and Briquetting machine.

- Specify Scrap Chip Processing automation needs for Briquetting press PLC and Briquetting machine safety interlocks.

- Confirm Scrap Chip Processing installation space for Briquetting press layout and Briquetting machine service access.

- Define Scrap Chip Processing electrical limits to match Briquetting press auxiliaries and Briquetting machine hydraulics.

- Ask for Scrap Chip Processing remote support options for your Briquetting press and Briquetting machine.

- Set Scrap Chip Processing briquette density goals for Briquetting press settings and Briquetting machine tooling.

- Note Scrap Chip Processing downstream use (melting, selling) for Briquetting press and Briquetting machine selection.

- Clarify Scrap Chip Processing conveyor routing to feed the Briquetting press and Briquetting machine without bottlenecks.

- Request Scrap Chip Processing wear-part plan for Briquetting press tooling and Briquetting machine maintenance cadence.

- Provide Scrap Chip Processing shift pattern so Briquetting press duty and Briquetting machine uptime are aligned.

- Confirm Scrap Chip Processing commissioning needs for Briquetting press start-up and Briquetting machine training.

Terminology note

For clarity in Scrap Chip Processing discussions, many buyers use Briquetting machine as shorthand for the Briquetting press. Here, the Briquetting press is the Briquetting machine that compacts chips, the Briquetting machine is fully automatic, and Briquetting machine terminology is used in RFQs.

Are you following our LinkedIn account?