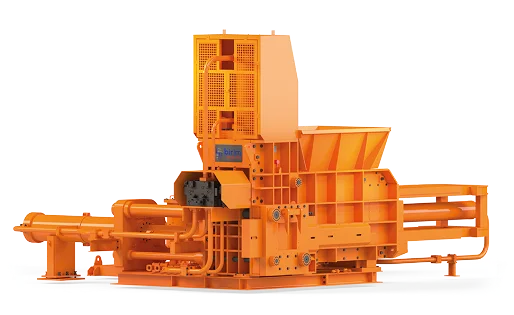

Puma – 2 Compression Balers

Baling press with 2 compression for metal scrap

About Puma 2 Ram Baler

This compact yet powerful scrap processing machine, with a capacity of 1 to 9 tons per hour, is ideal for scrap yards and casting plants, offering automatic operation via remote control. It efficiently handles Fe, Al, Cu, Cr-Ni scrap, sheets, and aluminum extrusions, featuring no-contact sensors, advanced oil filtration, and a robust structure with Hardox wear plates and high-quality hydraulic components designed for heavy-duty performance with low energy consumption.

Operation

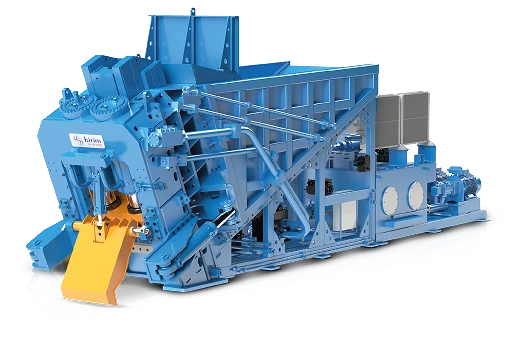

- Capacity : 1 – 10 tons per hour.

- Suitable input materials : Steel, Aluminum, Stainless Steel, Copper and Brass in forms of Sheets, Car parts, Profiles, Mixed Scrap, Cables, Cans and Wires.

- Automatic and manual operation

- Reduced scrap feeding time by the optional hopper.

- High density bales with a variety of bale sizes from 30×50 to 70×100 cm.

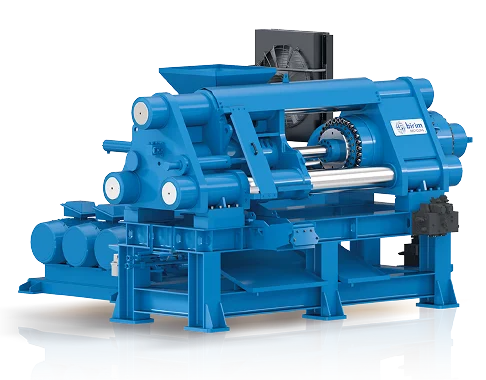

- Remote diagnosis and trouble shooting via modem connection enables quick technical assistance

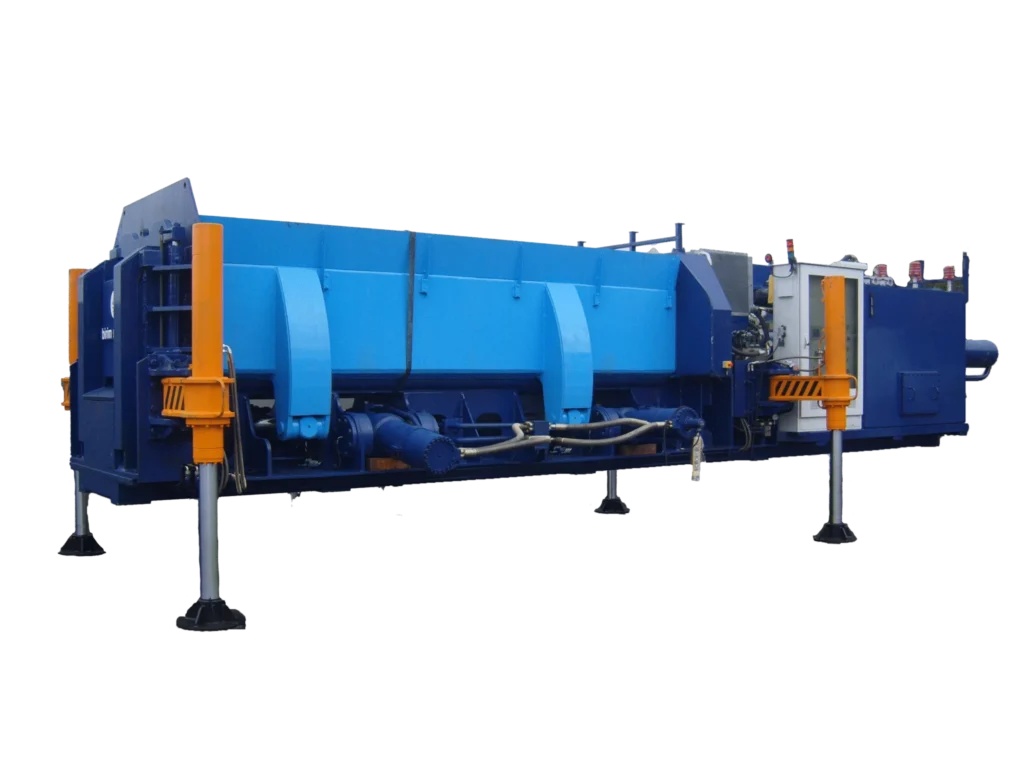

Structure

- Strong built body parts for Heavy Duty operation.

- Wear plates made of premium Hardox products with different profile shapes to suit the input material.

- Non-contact sensors in the machine prevents interruptions due to dirt and falling scrap.

- Heavy duty cylinders designed and manufactured in house.

- Hydraulic system designed and manufactured in house.

- Tier 1 parts in the machine supplied by Bosch Rexroth, Siemens, Baluff, Hydac.

Get in Touch

Contact us for information!

FAQ

General Questions About Puma

Find answers to common questions about Puma here. If you need more information, feel free to contact us!

What is the processing capacity of this machine?

The machine has a processing capacity ranging from 1 to 9 tons per hour, making it suitable for small to mid-scale operations.

Which materials can this machine process?

It can handle ferrous and non-ferrous materials such as Fe, Al, Cu, Cr-Ni, along with sheets and aluminum extrusions.

What makes this machine reliable and efficient in daily operations?

It features automatic remote-controlled operation, no-contact sensors that eliminate the need for recalibration, an oil filtering system for smooth performance, and a durable Hardox-lined structure with high-efficiency hydraulic components.